Do Drone-less wind farms stay behind? Yes, they do.

Offshore wind farms can’t ignore those trends – drones are becoming absolutely indispensable equipment for servicing, maintaining, and monitoring turbines. Using drones is no longer building an advantage over the competition, but only a necessary tool to stay in the peloton.

With each passing quarter and year, subsequent industries and companies notice the looming – or even ongoing – revolution of using new technology to increase efficiency and reduce operating costs of services and production. The time of drones is coming – fast, effective, relatively cheap to maintain, and extremely precise devices that already replace human work. Drones have proven to be extremely beneficial in accessing places humans cannot reach or enter and on tasks humans are unable to perform in a timely and efficient manner.

However, there are also such industries in which human labor costs are exceptionally high – due to their narrow specialization, a limited number of professionals, difficult working conditions, or the absolute need to carry out periodic and very precise inspections. Offshoring is such an industry. Experts have no doubt – the future of work related to inspection, monitoring, and offshoring control, especially in wind farms, is drone technology.

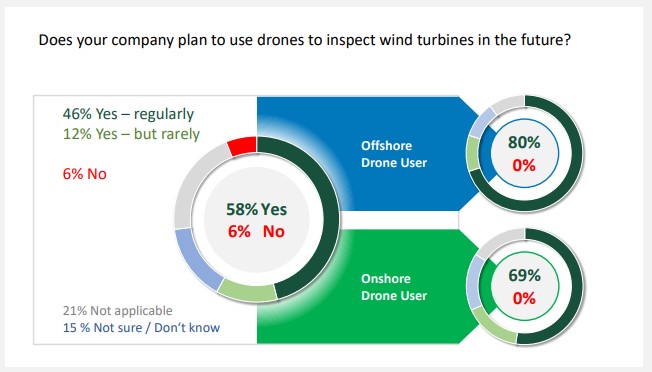

One figure from a 2019 survey by The Future Energy Consulting Company (TFECC – here) says more than a few paragraphs – 80%. 80% of companies plan to continue using drones to inspect offshore wind turbines in the future (the remaining 20% is not applicable or don’t know).

„The subgroup analysis of those respondents whose companies already used drones for inspection of onshore or offshore wind turbines is extremely clear: not a single one (0%) plans not to use drones in the future” – reads the report.

Today, therefore, we do not ask “whether” drones will replace human work, but “when” and „in what”. Looking at the research results, experts’ statements, and anticipating the further development of drone technology, there is no doubt that today drones are for the offshore industry what mechanical tractors were for agriculture in the second half of the twentieth century.

Companies operating wind farms that do not use or will not start using UAV services shortly will stay behind. They will be cost-ineffective and operationally ineffective, more prone to human errors and omissions – in short: less competitive.

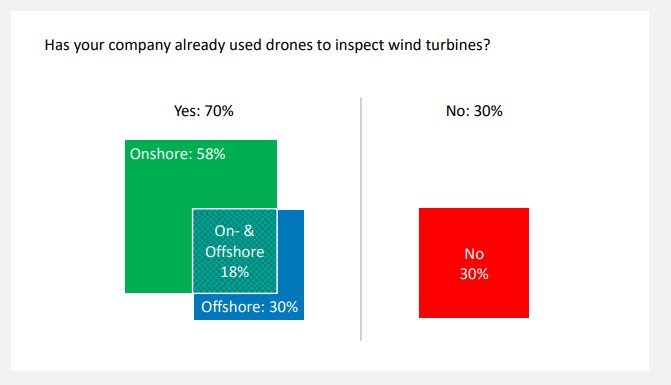

As for 2019, 70% of wind farm operators were using drones to inspect turbines. „The 30% of the respondents that have not used drones so far for inspection purposes are typically working for companies that are investors, installers, O&M operators, etc. or are with associations or academic and research organizations and do not inspect wind turbines as part of their business activities” – reads the report.

DRONES? NOT ONLY SAFETY AND COSTS. ALSO PRECISION

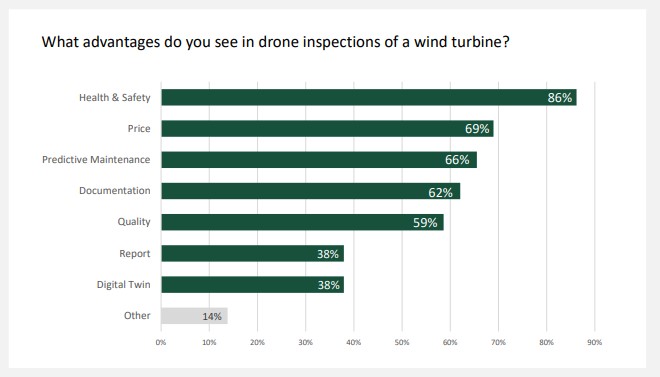

Let’s look at the next graphics showing the results of the TFECC study.

Safety issues, identified in the survey as the most important factor in favor of the use of drones, is an expected response. Human work, even with an onshore wind farm, is considered dangerous, let alone factors related to much stronger wind, swinging waves, or the inability to quickly evacuate. On the other hand, as experts emphasize, drones have a greater and greater advantage over humans in the area of precision and data analysis.

“More and more companies see the advantage of extremely accurate, sensitive, and error-free data that a drone can collect. Properly programmed, with appropriate algorithms, it can absolutely flawlessly compare several hundred data from many flights to indicate which blade element shows signs of wear”- tells us Vadym Melnyk, Dronehub founder and CEO.

He adds that only those drone manufacturers who will have an advantage in both software and hardware are suitable for inspecting hard-to-reach industrial areas such as offshore wind farms and oil & gas platforms. Dronehub is a European leader in comprehensive drone-in-a-box solutions. It is the only manufacturer in the world to provide a docking station that enables automatic battery replacement in a drone. Thanks to this innovative solution, Dronehub drones can perform missions 24/7 without human intervention.

The greatest challenge for drone constructors is the extreme conditions in which they must confirm the reliability of the machine – very strong and variable gusts of wind, salinity, high air humidity, the risk of a strong water wave.

“The work of drones in such a difficult environment requires perfect preparation of both the machine and the software. The reality and requirements of offshore customers will quickly verify the market. That is why we are working hard to maintain our competitive advantage, both in terms of software and hardware” – adds Melnyk from Dronehub.

ONE NEW TURBIN WITH EACH SPIN

The demand for drones for monitoring and inspection of wind energy installations will grow not only due to the growing utility of these machines and their indispensability in this industry. Also because with the green wave of energy – or rather the wave of green energy – the global number of offshore installations for energy production will grow. The number of new wind farms and hence more turbines is growing rapidly. Hyperbolically – with every rotation of the blade, a new turbine appears somewhere in the world.

Not only the richest countries in the world (Scandinavia, North America, UK, Germany) but also less affluent economies will switch to obtaining energy from wind. According to the International Energy Agency report (2019) a global wind power capacity is forecast to grow 62% by 2024, with onshore wind expected to grow 57% to 850 GW and offshore wind to nearly triple to 66 GW.

One of the large European energy companies that are dynamically developing in the wind farm sector is PGE, which is the owner of PGE Baltica, a special purpose vehicle responsible for implementing the Offshore Program at PGE. PGE Baltica plans to build three offshore wind farms in the Polish part of the Baltic Sea, with a total maximum capacity of up to 3.5 GW. Are they planning to use drone systems and when for construction or maintenance?

“As the first investments will enter the operational phase around 2026, we are not yet using drones for their exploitation. However, we plan to use them for the maintenance of the above-mentioned projects” – tells us Karol Mitraszewski, an expert in wind measurements and turbine placement at PGE Baltica.

As the most important activities performed by UAV drones on wind farms, Mitraszewski lists monitoring of blades condition especially early detection of the blade leading edge erosion, airborne magnetic surveys, and aerial LiDAR and photogrammetry surveys.

PROPELLERS + HANDS = FULL SERVICE COVERAGE

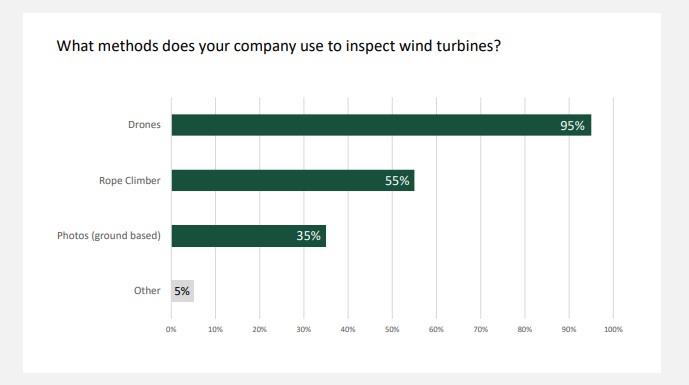

Research shows that although almost all (95%) companies already use drones, still the majority (55%) also use human work as well. No doubts, the men’s hands will still be needed – the drone can measure, photograph, count, indicate and alert. However, the physical operations at the windmills will still be performed by rope-climbers.

“To some extent, drones will become a useful tool lowering the maintenance costs significantly, but many tasks will still require human input like for example parts replacements, repairs, etc.” – adds Mitraszewski, PGE Baltica expert.

„Drone inspections of wind turbines are even today superior to the traditional rope climber and there are clear indications that drones will become the predominantly used method for wind turbine inspections. Rope climbers and professional service staff will not disappear but will be seen mainly in performing maintenance and repair work that cannot be performed by drones. For reoccurring routine inspections, drones offer many advantages and, as we have seen in other industries before, such work can be done by flying robots much safer, faster, and cheaper” – reads the report.

To have a full scope of view, we asked an experienced rope-climber about his approach to UAV role in the industry.

“There is no doubt that our role is changing with the advancement of drone technology. Currently, the largest and most modern companies only use drones for work related to monitoring, inspection, or measurements. This is a trend that will not stop. However, the work of our hands is still necessary for physical repairs or assembly” – tells us Jan Przasnek from the Rope Access Team company, who has been working as an offshore rope access technician in the waters of Europe, Asia, and North America since 2013.

So it seems that the optimal set for servicing wind farms is as follows: drone technology, taking on by far the greatest burden of tasks, supported by human hands, necessary only for repair work.

Now that we know what advantages drones have and that the vast majority of companies use and will use them, let’s look at what activities their use will be the most common. The TFECC report results: podium occupy ex aequo three roles (79% each): „regular inspections”, „documentation of damages”, and „data for predictive maintenance”. They are followed by „data for digital twin” (38%), „monitoring of construction phases” (31%), „material supply” (24%), and „other” (10% combined).

“These three roles are the future of industrial drone systems. We noticed these needs at the early stage of our company’s development, thanks to which we had the time and opportunities to specialize in the creation of comprehensive systems for monitoring, inspection, and data collection”- says Melnyk from Dronehub.

In the conclusion of this text, let us quote the report once again: „And one thing is very clear: you must act fast. Now is the time to get into the game, to make your own experiences and walk through your learning curve – and to develop a sound strategy that includes drones as an integral part of your future business model”.

Thanks for reading this text. It took you ca. 6 min. Think of how many new turbines appeared somewhere in the world in the meanwhile…